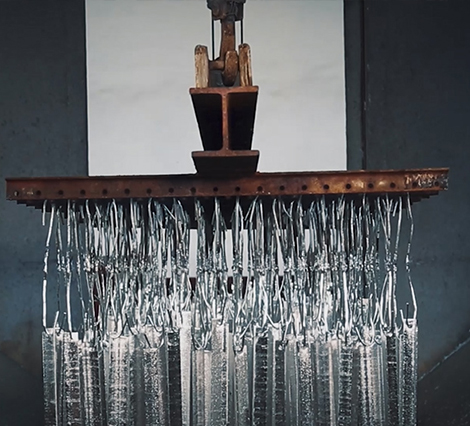

Hot dip galvanizing is the process of dipping steel into a pool of molten zinc. It has more distinct advantages over other corrosion prevention methods.

When iron or steel material is immersed in a zinc pool, it forms a strong alloy coating that provides protection on molten zinc materials.

For most metals, the causes of corrosion are the same. The main cause and mechanism of occurrence are based on electro-chemical causes. Corrosion poses serious and enormous dangers for structural steel. Corrosion causes rusting as a result of different atmospheric environments. This corrosion is a chemical deterioration.

Iron and steel materials lose their chemical and electrical properties from this corrosion. In particular, these metals are the fastest oxidized metals in the atmosphere and eroded by destruction.

The most effective and economical solution that basically protects steel and iron surfaces from contact with the atmosphere is zinc coating with hot dip galvanizing method.

Hot dip galvanizing is the coating of iron and steel by dipping into molten zinc. The entire surface of the material immersed in the zinc pool is covered with zinc up to the smallest point.

The coating surface, which has a shiny appearance first, becomes dull over time and creates a gray protective zinc layer. Thanks to this protection, it delays the corrosion of materials from 15 to 80-100 years.

Such protection is not found in paint or any other biological protection option. The coating layer is removed for damaged areas in materials protected by plastic coating or paint. For this reason, they are not safe and long-lasting compared to zinc coating. Since rust formation from the material cannot be prevented, a continuous maintenance will be required.

Even if damage to the coating occurs, zinc protects the steel in this area. If the coating decomposes naturally, an additional protective layer is formed on the surface.

Although the paint seems more suitable when evaluated in terms of cost, it is also understood that hot dip galvanization is more economical considering its long life.

A hot-dip galvanized product can be used for many years without any maintenance or repair.

For all these reasons, the most logical and economical solution to protect iron and steel against rusting is the hot dip galvanizing method.